Standardized use and maintenance, fully utilizing the performance of Yantai CNC rotary tables

Published time:

2025-05-28

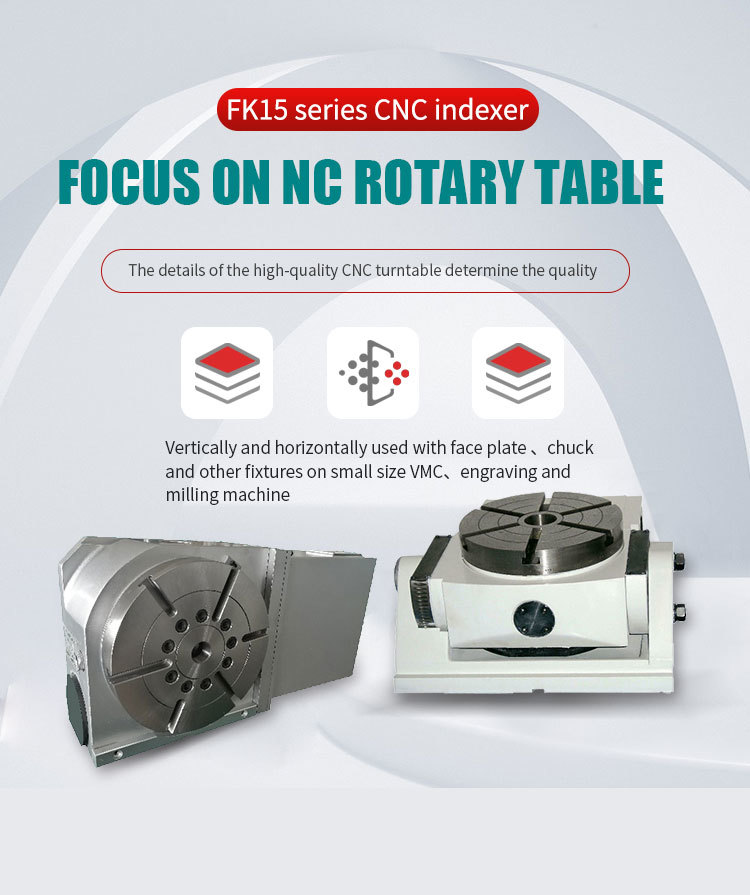

Yantai CNC turntables are renowned for their high precision and reliability, but to fully utilize their performance, proper use and regular maintenance are essential. The following points require special attention when using a Yantai CNC turntable:

Yantai CNC turntables are known for their high precision and reliability, but to fully utilize their performance, proper use and regular maintenance are essential. The following are points to pay special attention to when using a Yantai CNC turntable:

Installation and Debugging Key Points

The installation base must be precisely ground, with planarity ≤0.01mm/m

Use a high-precision level to adjust the level, with an error ≤0.02mm/m

Cable wiring should avoid running parallel to power lines to prevent interference

Daily Use Standards

Pre-heat by idling at low speed for 10 minutes before starting

Strictly prohibit exceeding the rated speed

Load installation should be balanced, with eccentricity controlled within the allowable range

Maintenance Requirements

Replace the special lubricating grease every 500 hours

Check the meshing condition of the worm gear and worm every month

Clean the encoder reading head every quarter

Fault Prevention Measures

Observe for abnormal vibrations and noise

Regularly check the reliability of electrical connections

If accuracy decreases, compensate promptly

Environmental Requirements

Control the operating environment temperature to 18-24℃

Maintain relative humidity at 40%-60%

Avoid dust and corrosive gases

Yantai CNC turntable users should establish complete usage and maintenance records and regularly contact the manufacturer for professional testing and maintenance. Through proper use and careful maintenance, the Yantai CNC turntable can maintain long-term stable processing accuracy, and its service life can reach more than 10 years.

Related News

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

COOKIES

Our website uses cookies and similar technologies to personalize the advertising shown to you and to help you get the best experience on our website. For more information, see our Privacy & Cookie Policy

These cookies are necessary for basic functions such as payment. Standard cookies cannot be turned off and do not store any of your information.

These cookies collect information, such as how many people are using our site or which pages are popular, to help us improve the customer experience. Turning these cookies off will mean we can't collect information to improve your experience.

These cookies enable the website to provide enhanced functionality and personalization. They may be set by us or by third-party providers whose services we have added to our pages. If you do not allow these cookies, some or all of these services may not function properly.

These cookies help us understand what you are interested in so that we can show you relevant advertising on other websites. Turning these cookies off will mean we are unable to show you any personalized advertising.

Contact Us

Address: No. 3, Futan Road, Fudong Industrial Park, Fushan District, Yantai City

-

-

Technical support

-

After-sales service

-

E-mail