2025 CNC Turntable Industry Trends: Explosive Demand and Accelerated Domestic Substitution

Published time:

2025-06-25

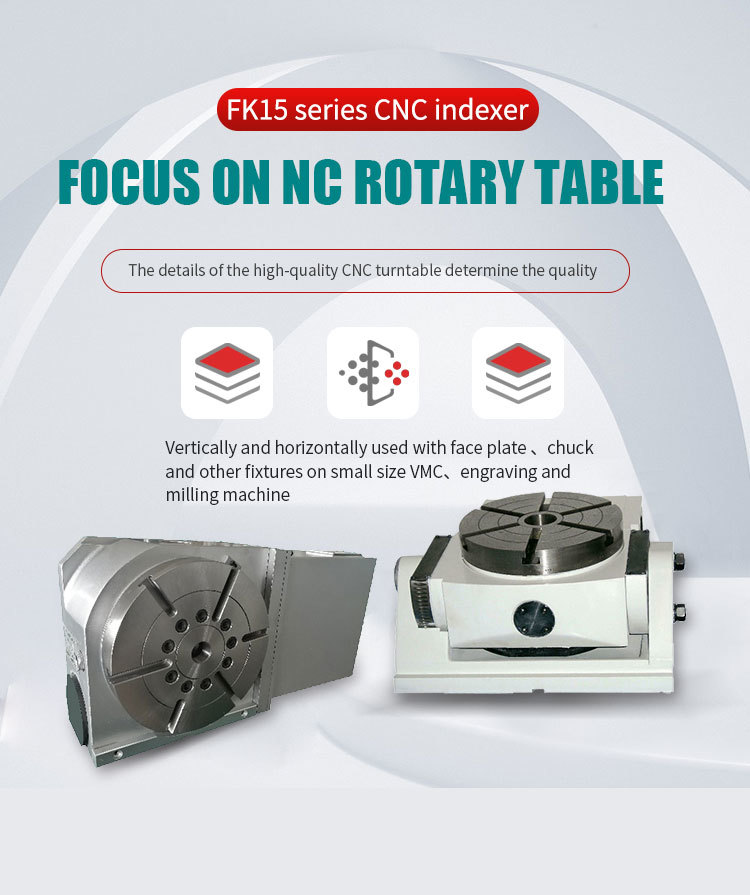

As a key functional component enabling multi-axis linkage in CNC machine tools, the CNC rotary table undertakes the core task of precise workpiece rotation and positioning, directly determining the machine tool's machining accuracy and complex surface machining capabilities. With the urgent need for high-precision and high-efficiency processing in China's high-end manufacturing industry, the CNC rotary table industry is experiencing unprecedented development opportunities.

I. Current Market Situation: Soaring Demand and Domestic Shortcomings Coexist

Scale and Growth Rate CICC predicts that the domestic demand for CNC rotary tables in 2025 will exceed 110,000 units ,2021-2025年行业复合增长率达15% The compound annual growth rate of the industry from 2021 to 2025 is significantly higher than the overall growth rate of the machine tool industry. In terms of revenue, the market size is expected to exceed US$836 million (approximately RMB 6 billion) in 2025, with a CAGR of 12% from 2020 to 2025.

Competitive Landscape Currently, the domestic market is dominated by Taiwanese companies In 2021, the top 5 companies were all Taiwanese brands, with a market share as high as 56%. Domestic companies are generally concentrated in the mid-to-low-end market. Although domestic manufacturers such as Haozhi Electromechanical and Yantai Nanjing Gongda CNC Intelligent Equipment Co., Ltd. have already started, they have not yet made effective breakthroughs in the high-end field.

Technological Bottlenecks There are obvious shortcomings in key upstream links of the industrial chain:

YRT bearings have a domestic production rate of less than 50%, and high-precision products rely on imports;

in the encoder field, the overseas monopoly rate exceeds 90% ;

The reliability of motors lags behind international standards.

Midstream manufacturing is constrained by the strong non-standard attributes of rotary tables and the strict confidentiality of precision processes.

II. Technological Evolution: Direct Drive Leads Multi-Route Parallel Development

The driving technology of CNC rotary tables is moving towards high efficiency, zero backlash, and high responsiveness This has resulted in four competing technological approaches:

Worm gear: Currently the mainstream solution, with strong load-bearing capacity, but requiring regular backlash elimination maintenance, suitable for heavy-duty machining scenarios;

Cam roller: Offers zero backlash and long lifespan advantages, but cam processing technology has a high entry barrier and high cost;

Precision reducer (Harmonic/RV/Planetary): Companies in the robotics industry chain are crossing over into this field, with significant potential for technology reuse;

Direct drive motor (DD motor): As a leading-edge direction, with its high dynamic response and no mechanical loss characteristics, it is accelerating penetration in the field of combined milling and turning, and is expected to exceed 30% of the high-end market share in 2025.

III. Domestic Breakthrough: The Innovative Practices of Yantai Nanjing Gongda CNC Intelligent Equipment Co., Ltd.

Yantai Nanjing Gongda CNC Intelligent Equipment Co., Ltd. As a subsidiary of Nanjing University of Technology CNC Technology Holding Company, relying on the technological accumulation of its parent company, a national-level specialized and new “small giant”, it has become a representative of breakthroughs in domestic high-end rotary tables. Its technological breakthroughs are reflected in three dimensions:

Core Product Innovation :

The company's various series of products have been applied in various industrial fields, including aerospace and new energy equipment.

Independent Core Technology :

The company holds more than 80 invention patents and more than 40 software copyrights, forming barriers in patent groups such as “polar coordinate CNC gear processing” and “digital performance testing platform”, breaking through the technological blockade of overseas companies.

Deepening Strategic Layout :

In 2024, the company clarified its “dual circulation” strategy, accelerating penetration into the high-end market through international exhibitions such as Shanghai CCMT2024, and extending to upstream core components of rotary tables based on Nanjing University of Technology's layout in functional components.

IV. Future Trends: Domestic Substitution and Intelligent Upgrades

The industry will usher in three structural opportunities in 2025:

Window of Opportunity for Domestic Substitution :

Driven by policy support and supply chain security needs, domestic companies are expected to achieve high-end breakthroughs in aerospace and new energy equipment fields Domestic manufacturers such as Nanjing Gongda Global are accelerating the process of independent development of core components such as bearings and encoders through vertical integration.

Accelerated Popularization of Direct Drive Technology :

With the growth in demand for combined milling and turning, the cost of direct drive rotary tables is expected to decrease by 25%-30%, and the penetration rate in fields such as precision medical equipment and optical devices will rapidly increase.

Integration of Intelligence and Green Manufacturing :

Internet of Things technology is driving rotary tables towards predictive maintenance upgrades, such as Nanjing Gongda Global's equipment integrated online measurement system, which enables real-time compensation of machining errors; low-carbon design concepts drive motor energy efficiency improvements and lightweight material applications, responding to the manufacturing industry's carbon neutrality goals.

Industry Challenges and Prospects

In 2025, as the high-end process of domestic machine tools accelerates, domestic CNC rotary tables are expected to occupy more than 20% of the high-end market share 。

The rise of China's CNC rotary table industry is not only a microcosm of the upgrading of functional components of domestic machine tools, but will also promote the realization of independently controllable high-precision manufacturing in strategic industries such as aerospace and new energy vehicles. When cold metal is given a precise rotation angle on a precision rotary table, the core components of numerous “major national projects” are thus born—this is a microcosmic testament to China's manufacturing advancement towards the high end.

Previous page

Previous page

Related News