Micron-Level Precision: The Journey of Yantai Nanjing Gongda CNC Technology's Global Intelligent Equipment's Precision Manufacturing

Published time:

2025-07-01

Nantong University Intelligent Equipment Production

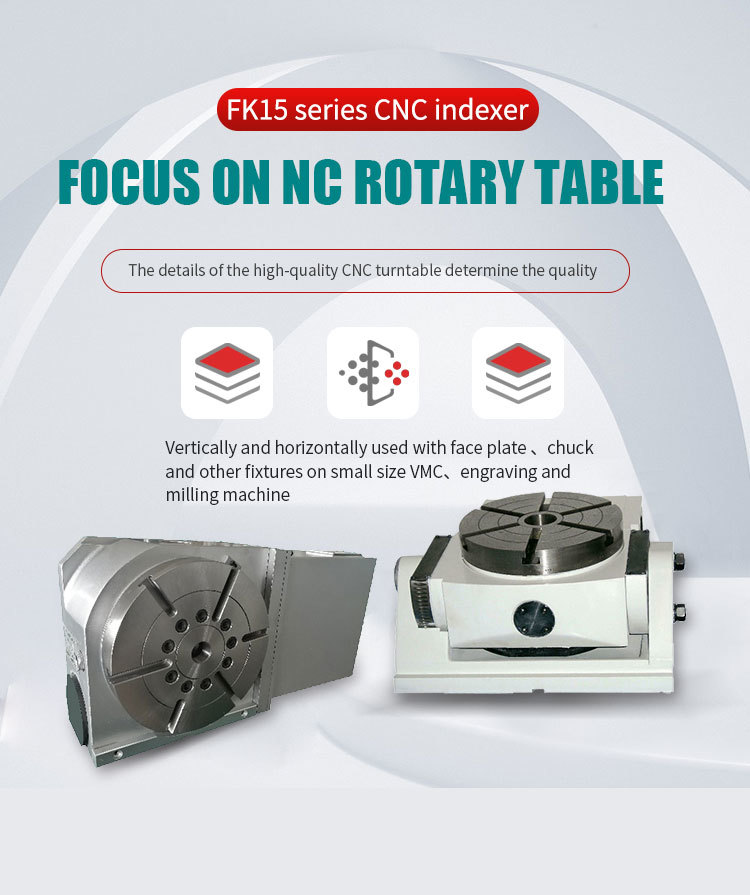

In a factory at No. 3, Futan Road, Fushan District, the laser interferometer's beam is projected onto a massive object with a diameter of 5 meters. This φ5000mm CNC rotary table is about to undergo its final precision test—its rotational error is controlled to within 4 micrometers, equivalent to the diameter of a bacterium. Engineers from Yantai Nanjing Gongda CNC Intelligent Equipment Co., Ltd. lightly touch the screen, and data is transmitted back to the control center in real time. This equipment, embodying core technology in worm gear manufacturing, is about to be shipped to a high-end machine tool factory in China, becoming a "joint" of industrial mother machines. This is a daily scene of Yantai's intelligent equipment manufacturing, and also a microcosm of the independent development of high-end machine tool functional components in China.

In May 2021, a new force was born in Yantai's intelligent manufacturing field. Nanjing Gongda CNC Technology Co., Ltd. and Yantai Global Machine Tool Equipment Co., Ltd. joined forces to establish Yantai Nanjing Gongda CNC Intelligent Equipment Co., Ltd. This company has targeted a key area once monopolized by foreign countries—CNC rotary tables.

Technical Core and Workshop Scene: The Foundation of Precision Manufacturing

Entering the manufacturing workshop of Yantai Nangongda Global Intelligent Equipment, a professional production scene is clearly presented:

Equipment Layout and Processing: Dozens of key processing equipment are arranged in an orderly manner in the workshop, including precise CNC thread grinders and CNC hobbing machines. Under the continuous operation of these equipment, raw materials (steel billets) are undergoing a strict process from rough machining to fine machining, gradually forming into high-precision components.

Precision Assurance: The laser interferometer is the core testing equipment, used for the final verification of the key rotational precision of the assembled CNC rotary table products. Its detection accuracy reaches the micrometer level, ensuring that the product performance meets the design requirements.

Product Series Coverage: The company has the ability to produce a full series of CNC rotary tables, with a wide range of product specifications, from desktop-level φ100mm miniature rotary tables suitable for small equipment to φ5000mm giant rotary tables weighing several tons and used in large-scale equipment, meeting the diverse needs of customers in various industries.

Production Capacity and Market Verification:

Relying on mature technology and a highly efficient manufacturing system, the company currently has the capacity to produce more than 3,000 CNC rotary tables of various types annually. Its products have been stably supplied to more than 100 domestic manufacturing enterprises, including Chery and Geely, and are widely used in machine tools, automated production lines, and other fields. The stable market performance and customer recognition also mark the foothold of high-end functional components of "Yantai intelligent manufacturing" in the domestic market, and gradually expanding into the international market.

The precision manufacturing of Nangongda Global Intelligent Equipment forms an industrial synergy: one focuses on breakthroughs in basic components, and the other creates complete machine system integration, jointly outlining the industrial chain panorama of Yantai's "basic components-high-end equipment".

Looking back from mid-2025, Yantai Nangongda Global Intelligent Equipment has completed the transformation from a newcomer to a leader in four years. When the φ5000mm rotary table rotates smoothly on the test bench, every micrometer of its precision is engraved with the touch of the craftsman's fingertips and the logic of the code; every rotation drives the forward direction of domestic high-end machine tool functional components.

In the arena of intelligent equipment, Yantai manufacturing is proving its strength: with precision to forge the core, and with ingenuity to control intelligence, the path to independent development of China's high-end equipment is long and arduous, but it will eventually arrive.

Production

Previous page

Previous page

Related News